Plastic waste poses an ecological challenge and enzymatic degradation offers one, potentially green and scalable, route for polyesters waste recycling. Polyethylene terephthalate (PET) accounts for 12% of global solid waste, and a circular carbon economy for PET is theoretically attainable through rapid enzymatic depolymerization followed by repolymerization or conversion/valorization into other products. Application of natural enzymes called PET hydrolases, however, has been hampered by their lack of robustness to pH and temperature ranges, slow reaction rates and inability to directly use untreated postconsumer plastics. In new research, a team of scientists at the University of Texas at Austin used a structure-based, machine learning algorithm to engineer a robust and active enzymes: FAST-PETase (functional, active, stable and tolerant PETase).

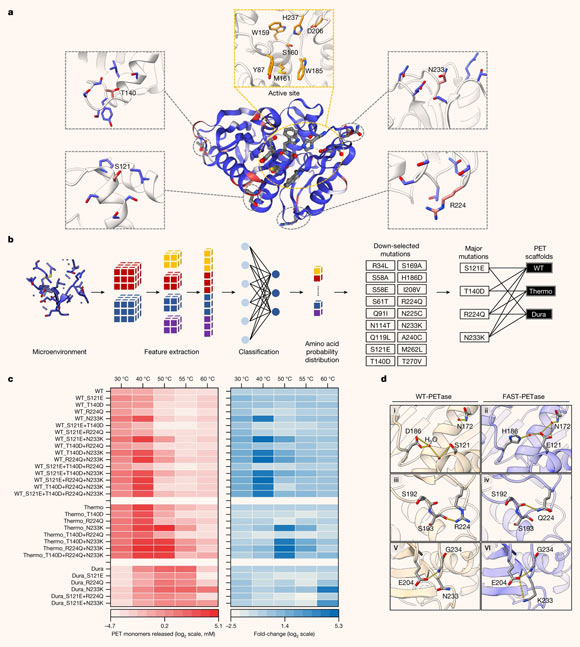

Machine learning guided predictions improve enzyme performance across PETase scaffolds. Image credit: Lu et al., doi: 10.1038/s41586-022-04599-z.

“The possibilities are endless across industries to leverage this leading-edge recycling process,” said Professor Hal Alper, a researcher in the McKetta Department of Chemical Engineering at the University of Texas at Austin.

“Beyond the obvious waste management industry, this also provides corporations from every sector the opportunity to take a lead in recycling their products.”

“Through these more sustainable enzyme approaches, we can begin to envision a true circular plastics economy.”

Professor Alper and colleagues focused on PET, a significant polymer found in most consumer packaging, including cookie containers, soda bottles, fruit and salad packaging, and certain fibers and textiles. It makes up 12% of all global waste.

The enzyme was able to complete a circular process of breaking down the plastic into smaller parts (depolymerization) and then chemically putting it back together (repolymerization).

In some cases, these plastics can be fully broken down to monomers in as little as 24 hours.

The researchers used a machine learning model to generate novel mutations to PETases that allows bacteria to degrade PET plastics.

The model predicts which mutations in these enzymes would accomplish the goal of quickly depolymerizing post-consumer waste plastic at low temperatures.

Through this process, which included studying 51 different post-consumer plastic containers, five different polyester fibers and fabrics and water bottles all made from PET, the authors proved the effectiveness of the enzyme, which they are calling FAST-PETase.

“This work really demonstrates the power of bringing together different disciplines, from synthetic biology to chemical engineering to artificial intelligence,” said Professor Andrew Ellington, a researcher in the Department of Molecular Biosciences at the University of Texas at Austin.

The team’s paper was published in the journal Nature.

_____

H. Lu et al. 2022. Machine learning-aided engineering of hydrolases for PET depolymerization. Nature 604; doi: 10.1038/s41586-022-04599-z