A team of materials scientists and engineers from the Pennsylvania State University and Cranfield University has designed and fabricated a new toilet coating that can reduce cleaning water consumption by 90% compared with uncoated surfaces due to its extreme repellency towards liquids, bacteria and viscoelastic solids.

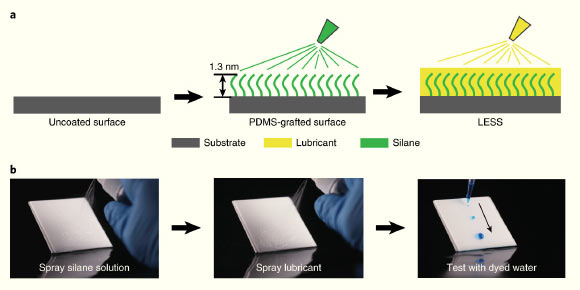

Fabrication of the liquid-entrenched smooth surface: (a) schematic showing the two-step spray-coating process to form the LESS coating; the molecularly grafted polymer layer creates chemical affinity to the lubricant; (b) optical images showing the individual coating processes on glass; the lubricant used was silicone oil, and the blue testing liquid was dyed water. Image credit: Wang et al, doi: 10.1038/s41893-019-0421-0.

Water scarcity threatens over half of the world’s population, yet over 141 billion liters of fresh water are used globally each day for toilet flushing. This is nearly six times the daily water consumption of the population in Africa.

The toilet water footprint is so large primarily because large volumes of water are necessary for the removal of human feces.

“We developed a robust bio-inspired, liquid, sludge- and bacteria-repellent coating that can essentially make a toilet self-cleaning,” said Penn State’s Professor Tak-Sing Wong, leader of the team and senior author of a paper published in the journal Nature Sustainability.

The new coating, dubbed the liquid-entrenched smooth surface (LESS), is a two-step spray that can be applied to a ceramic toilet bowl.

Created from molecularly grafted polymers, the first spray is the initial step in building an extremely smooth and liquid-repellent foundation.

“When it dries, the first spray grows molecules that look like little hairs, with a diameter of about 1,000,000 times thinner than a human’s,” said first author Jing Wang, a doctoral graduate at Penn State.

While this first application creates an extremely smooth surface as is, the second spray infuses a thin layer of lubricant around those nanoscopic ‘hairs’ to create a super-slippery surface.

“When we put that coating on a toilet in the lab and dump synthetic fecal matter on it, it (the synthetic fecal matter) just completely slides down and nothing sticks to the toilet,” Wang said.

With this novel slippery surface, the toilets can effectively clean residue from inside the bowl and dispose of the waste with only a fraction of the water previously needed.

The researchers also predict the coating could last for about 500 flushes in a conventional toilet before a reapplication of the lubricant layer is needed.

While other liquid-infused slippery surfaces can take hours to cure, the LESS two-step coating takes less than five minutes.

The team’s experiments also found the surface effectively repelled bacteria, particularly ones that spread infectious diseases and unpleasant odors.

“If it were widely adopted in the United States, it could direct critical resources toward other important activities, to drought-stricken areas or to regions experiencing chronic water scarcity,” the scientists said.

“Driven by these humanitarian solutions, we also hope our work can make an impact in the developing world.”

“The technology could be used within waterless toilets, which are used extensively around the world.”

_____

J. Wang et al. Viscoelastic solid-repellent coatings for extreme water saving and global sanitation. Nat Sustain, published online November 18, 2019; doi: 10.1038/s41893-019-0421-0