A new study published in the Journal of Cleaner Production is the first to prove that waste coffee grounds can be used to improve concrete.

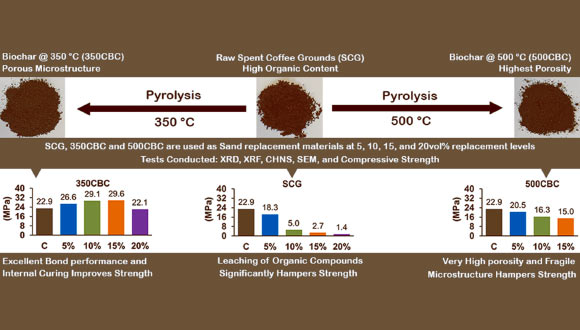

Roychand et al. show that the leaching of organic compounds from waste coffee grounds hinders the hydration reaction of cement particles, thereby significantly hampering the compressive strength of waste coffee ground-blended concrete; however, pyrolyzing waste coffee grounds at 350 degrees Celsius led to a significant improvement in its material properties, which resulted in a 29.3% enhancement in the compressive strength of the composite concrete blended with coffee biochar. Image credit: Roychand et al., doi: 10.1016/j.jclepro.2023.138205.

The decomposition of organic waste going to landfills produces methane gas, which is 21 times worse than carbon dioxide in its global warming potential.

Waste coffee grounds are one type of organic waste that makes up a significant proportion of the organic waste going to landfills.

Therefore, it becomes imperative to look for a recycling solution to transform this waste into a valuable resource.

“We developed a technique to make concrete 30% stronger by turning waste coffee grounds into biochar, using a low-energy process without oxygen at 350 degrees Celsius,” said RMIT University researcher Rajeev Roychand.

“The disposal of organic waste poses an environmental challenge as it emits large amounts of greenhouse gases including methane and carbon dioxide, which contribute to climate change.”

“The inspiration for our work was to find an innovative way of using the large amounts of coffee waste in construction projects rather than going to landfills — to give coffee a ‘double shot’ at life.”

“The concrete industry has the potential to contribute significantly to increasing the recycling of organic waste such as used coffee,” added RMIT University researcher Shannon Kilmartin-Lynch.

“Our research is in the early stages, but these exciting findings offer an innovative way to greatly reduce the amount of organic waste that goes to landfill.”

“The coffee biochar can replace a portion of the sand that was used to make concrete,” said RMIT University’s Professor Jie Li.

“The ongoing extraction of natural sand around the world — typically taken from river beds and banks — to meet the rapidly growing demands of the construction industry has a big impact on the environment.”

“50 billion tons of natural sand are used in construction projects globally every year”

“There are critical and long-lasting challenges in maintaining a sustainable supply of sand due to the finite nature of resources and the environmental impacts of sand mining.”

“With a circular-economy approach, we could keep organic out of landfill and also better preserve our natural resources like sand.”

“The construction industry needed to explore alternative raw materials to ensure its sustainability,” said RMIT University researcher Mohammad Saberian.

“Our research team has gained extensive experience in developing highly optimized biochars from different organic wastes, including wood biochar, food-waste biochar, agricultural waste biochar, and municipal solid-waste biochar, for concrete applications.”

_____

Rajeev Roychand et al. 2023. Transforming spent coffee grounds into a valuable resource for the enhancement of concrete strength. Journal of Cleaner Production 419: 138205; doi: 10.1016/j.jclepro.2023.138205