Assembled from hundreds of tiny identical pieces, the new wing can change shape to control the plane’s flight. The wing design was tested in NASA’s high-speed wind tunnel at Langley Research Center and is described in a paper published online in the journal Smart Materials and Structures.

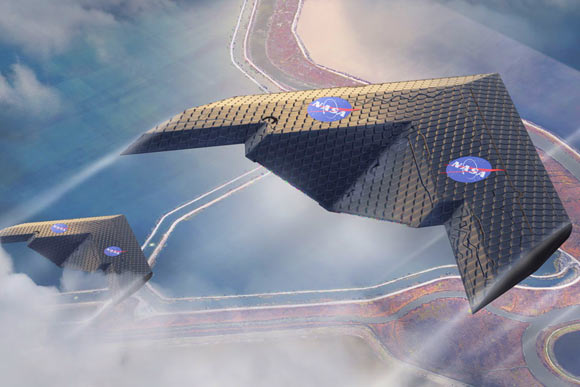

New way of fabricating aircraft wings could enable radical new designs, such as this concept, which could be more efficient for some applications. Image credit: Eli Gershenfeld, NASA’s Ames Research Center.

“Instead of requiring separate movable surfaces such as ailerons to control the roll and pitch of the plane, as conventional wings do, the new assembly system makes it possible to deform the whole wing, or parts of it, by incorporating a mix of stiff and flexible components in its structure,” explained co-author Benjamin Jenett, a graduate student in MIT’s Center for Bits and Atoms, and his colleagues.

“The tiny subassemblies, which are bolted together to form an open, lightweight lattice framework, are then covered with a thin layer of similar polymer material as the framework.”

“The result is a wing that is much lighter, and thus much more energy efficient, than those with conventional designs, whether made from metal or composites.”

Because the structure, comprising thousands of tiny triangles of matchstick-like struts, is composed mostly of empty space, it forms a mechanical metamaterial that combines the structural stiffness of a rubber-like polymer and the extreme lightness and low density of an aerogel.

“For each of the phases of a flight — takeoff and landing, cruising, maneuvering and so on — each has its own, different set of optimal wing parameters, so a conventional wing is necessarily a compromise that is not optimized for any of these, and therefore sacrifices efficiency,” Jenett said.

“A wing that is constantly deformable could provide a much better approximation of the best configuration for each stage.”

While it would be possible to include motors and cables to produce the forces needed to deform the wings, the team designed a system that automatically responds to changes in its aerodynamic loading conditions by shifting its shape — a sort of self-adjusting, passive wing-reconfiguration process.

“We’re able to gain efficiency by matching the shape to the loads at different angles of attack. We’re able to produce the exact same behavior you would do actively, but we did it passively,” said lead author Dr. Nicholas Cramer, of NASA’s Ames Research Center.

“This is all accomplished by the careful design of the relative positions of struts with different amounts of flexibility or stiffness, designed so that the wing, or sections of it, bend in specific ways in response to particular kinds of stresses.”

The team demonstrated the basic underlying principle a few years ago, producing a wing about a meter long, comparable to the size of typical remote-controlled model aircraft. The new version, about five times as long, is comparable in size to the wing of a real single-seater plane and could be easy to manufacture.

While this version was hand-assembled by the team, the repetitive process is designed to be easily accomplished by a swarm of small, simple autonomous assembly robots.

“The individual parts for the previous wing were cut using a waterjet system, and it took several minutes to make each part,” Jenett said.

“The new system uses injection molding with polyethylene resin in a complex 3D mold, and produces each part — essentially a hollow cube made up of matchstick-size struts along each edge — in just 17 seconds, which brings it a long way closer to scalable production levels.”

“The resulting lattice has a density of 5.6 kg/m3. By way of comparison, rubber has a density of about 1,500 kg/m3.”

“They have the same stiffness, but ours has less than roughly one-thousandth of the density.”

Because the overall configuration of the wing or other structure is built up from tiny subunits, it really doesn’t matter what the shape is.

“You can make any geometry you want. The fact that most aircraft are the same shape — essentially a tube with wings — is because of expense,” Jenett said.

“It’s not always the most efficient shape. But massive investments in design, tooling, and production processes make it easier to stay with long-established configurations.”

_____

Nick Cramer et al. 2019. Elastic Shape Morphing of Ultralight Structures by Programmable Assembly. Smart Mater. Struct, in press; doi: 10.1088/1361-665X/ab0ea2