A team of researchers at the Pennsylvania State University has demonstrated that they can charge an electrical vehicle in 10 minutes for a 200 to 300 mile (300-500 km) range.

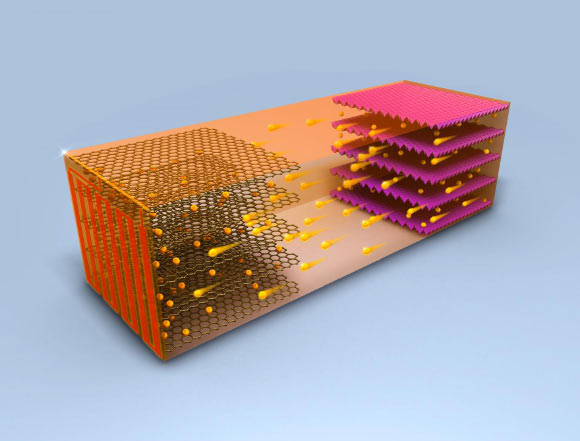

In a battery, ions flow from the cathode to the anode, resulting in a positive energy charge for the unit. Image credit: Chao-Yang Wang Lab, Penn State.

Lithium-ion batteries degrade when rapidly charged at ambient temperatures under 50 degrees Fahrenheit (10 degrees Celsius) because, rather than the lithium ions smoothly being inserted into the carbon anodes, the lithium deposits in spikes on the anode surface.

This lithium plating reduces cell capacity, but also can cause electrical spikes and unsafe battery conditions.

Batteries heated above the lithium plating threshold, whether by external or internal heating, will not exhibit lithium plating.

“In addition to fast charging, this design allows us to limit the battery’s exposure time to the elevated charge temperature, thus generating a very long cycle life,” said team leader Dr. Chao-Yang Wang, a mechanical engineer at the Pennsylvania State University.

“The key is to realize rapid heating; otherwise, the battery will stay at elevated temperatures for too long, causing severe degradation.”

In order to shorten heat time and heat the entire battery at a uniform temperature, Dr. Wang and colleagues outfitted a lithium ion battery design with a self-heating nickel structure that preheats in less than thirty seconds.

To test their model, the scientists charged three graphite pouch cells designed for hybrid electric vehicles at 104, 120, and 140 degrees Fahrenheit (40, 49, and 60 degrees Celsius), as well as a control at 68 degrees Fahrenheit (20 degrees Celsius), using various cooling strategies to maintain constant charge temperatures.

To confirm that lithium plating did not occur, they later fully discharged the cells and opened them for analysis.

The team found that the batteries preheated to 140 degrees Fahrenheit (60 degrees Celsius) could sustain the extremely fast charging process for 1,700 cycles, while the control cell could only keep pace for 60 cycles.

At an average charge temperature between 120 and 140 degrees Fahrenheit (49 and 60 degrees Celsius), they did not observe any lithium plating.

The researchers also observed that an increased charge temperature greatly reduced the cooling necessary to maintain the cell at its initial temperature — the control cell generated 3.05 watt-hours, while the 140-degree-Fahrenheit (60-degree-Celsius) cell generated only 1.7 watt-hours.

“In the past, it was universally believed that lithium ion batteries should avoid operating at high temperatures due to the concern of accelerated side reactions,” Dr. Wang said.

“This study suggests that the benefits of mitigated lithium plating at the elevated temperature with limited exposure time far outweigh the negative impact associated with exacerbated side reactions.”

The technology is completely scalable because all the cells are based on industrially available electrodes.

The nickel foil increases the cost of each cell by 0.47%, but because the design eliminates the need for the external heaters used in current models, it actually lowers the cost of producing each pack.

Next, the authors are planning to take their design a step further.

“We are working to charge an energy-dense electric vehicle battery in five minutes without damaging it,” Dr. Wang said.

“This will require highly stable electrolytes and active materials in addition to the self-heating structure we have invented.”

The team’s work appears in the journal Joule.

_____

Xiao-Guang Yang et al. Asymmetric Temperature Modulation for Extreme Fast Charging of Lithium-Ion Batteries. Joule, published online October 30, 2019; doi: 10.1016/j.joule.2019.09.021