An international team of researchers from Hong Kong, Singapore, Korea and the United States has demonstrated that nanoscale (300 nm) single-crystalline and polycrystalline diamond needles could flex and stretch by as much as 9% without breaking, then return to their original configuration. The team’s results, published in the journal Science, could open the door to a variety of diamond-based devices for applications such as sensing, data storage, actuation, biocompatible in vivo imaging, optoelectronics, and drug delivery.

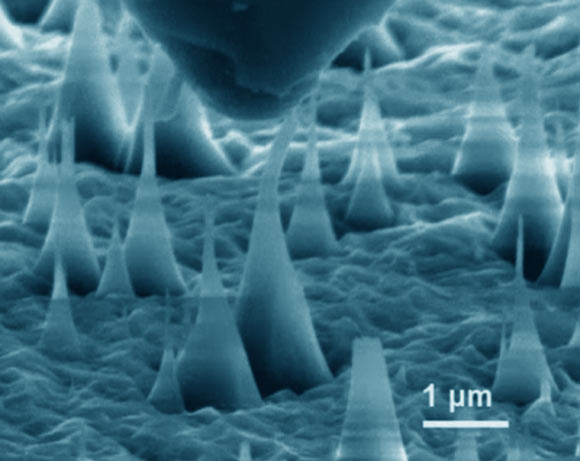

This scanning electron microscope image shows ultrafine diamond needles (cone shapes rising from bottom) being pushed on by a diamond tip (dark shape at top). These images reveal that the diamond needles can bend as much as 9% and still return to their original shape. Image credit: Banerjee et al.

“Ordinary diamond in bulk form has a limit of well below 1% stretch. It was very surprising to see the amount of elastic deformation the nanoscale diamond could sustain,” said co-author Dr. Daniel Bernoulli, a postdoctoral researcher in the Department of Materials Science and Engineering at MIT.

“We developed a unique nanomechanical approach to precisely control and quantify the ultralarge elastic strain distributed in the nanodiamond samples,” said co-lead author Dr. Yang Lu, a researcher with the City University of Hong Kong.

“Putting crystalline materials such as diamond under ultralarge elastic strains, as happens when these pieces flex, can change their mechanical properties as well as thermal, optical, magnetic, electrical, electronic, and chemical reaction properties in significant ways, and could be used to design materials for specific applications through ‘elastic strain engineering’,” the scientists said.

They measured the bending of the diamond needles, which were grown through a chemical vapor deposition process and then etched to their final shape, by observing them in a scanning electron microscope while pressing down on the needles with a standard nanoindenter diamond tip (essentially the corner of a cube).

Following the experimental tests using this system, the researchers did many detailed simulations to interpret the results and were able to determine precisely how much stress and strain the diamond needles could accommodate without breaking.

They also developed a computer model of the nonlinear elastic deformation for the actual geometry of the diamond needle, and found that the maximum tensile strain of the nanoscale diamond was as high as 9%.

The computer model also predicted that the corresponding maximum local stress was close to the known ideal tensile strength of diamond.

When the entire diamond needle was made of one crystal, failure occurred at a tensile strain as high as 9%.

Until this critical level was reached, the deformation could be completely reversed if the probe was retracted from the needle and the specimen was unloaded.

If the tiny needle was made of many grains of diamond, the study authors showed that they could still achieve unusually large strains. However, the maximum strain achieved by the polycrystalline diamond needle was less than one-half that of the single crystalline diamond needle.

“Our results were so surprising that we had to run the experiments again under different conditions just to confirm them,” said co-lead author Professor Subra Suresh, President of Nanyang Technological University, Singapore.

“We also performed detailed computer simulations of the actual specimens and bending experiments to measure and determine the maximum tensile stress and strain that the diamond nanoneedles could withstand before breaking.”

“This work also demonstrates that what is usually not possible at the macroscopic and microscopic scales can occur at the nanoscale where the entire specimen consists of only dozens or hundreds of atoms, and where the surface to volume ratio is large.”

“After two years of careful iterations between simulations and real-time experiments, we now know that the deformed shape of a bent nanoscale needle is the key in determining its maximum tensile strain achieved,” said co-lead author Dr. Ming Dao, from the Department of Materials Science and Engineering at MIT.

“The controlled bending deformation also enables precise control and on-the-fly alterations of the maximum strain in the nanoneedle below its fracture limit.”

_____

Amit Banerjee et al. 2018. Ultralarge elastic deformation of nanoscale diamond. Science 360 (6386): 300-302; doi: 10.1126/science.aar4165