A group of scientists at the University of Rochester has created a polymer material that undergoes a shape change that can be triggered by body temperature.

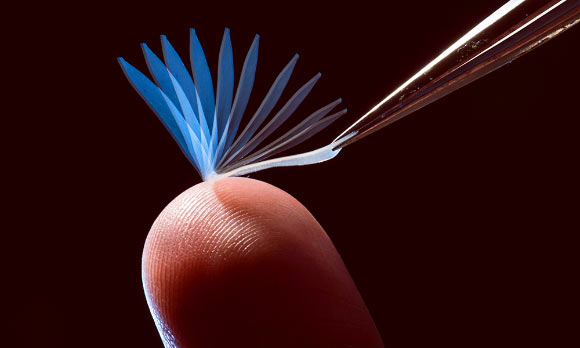

A time-lapse image of a previously deformed shape-memory network during recovery to its original shape upon contacting a finger in a room temperature environment. The image was obtained by periodic flash exposure over a time period of about 10 seconds. Image credit: J. Adam Fenster / University of Rochester.

“Shape-memory polymers are polymer networks that can be deformed and temporarily fixed into an elastically strained, non-equilibrium shape. Shape-fixing occurs when strong intermolecular interactions between configurationally distorted polymer chains overcome the chains’ entropic restoring forces,” the scientists explained in a paper in the Journal of Polymer Science Part B: Polymer Physics.

These polymers “are finding diverse applications, especially the biomedical field. Examples include clot removal devices, surgical sutures, dialysis needles, orthopedic suture anchors and vascular stents. These applications require that the trigger temperature should be near the human body temperature (37 degrees Celsius).”

The material developed by the University of Rochester research team not only can change its shape when exposed to a body temperature, but also can lift 1,000 times its own weight.

“For example, a polymer the size of a shoelace — which weighs about a gram — could lift a liter of soda,” the scientists said.

“We engineered this material to store large amount of elastic energy, enabling it to perform more mechanical work during its shape recovery,” explained co-author Prof. Mitch Anthamatten.

According to the team, the key to developing the new shape-memory polymer was figuring out how to control crystallization that occurs when the material is cooled or stretched.

As the material is deformed, polymer chains are locally stretched, and small segments of the polymer align in the same direction in small areas called crystallites, which fix the material into a temporarily deformed shape.

As the number of crystallites grows, the polymer shape becomes more and more stable, making it increasingly difficult for the material to revert back to its initial shape.

The ability to tune the trigger temperature was achieved by including molecular linkers to connect the individual polymer strands.

Prof. Anthamatten and co-authors discovered that linkers inhibit – but don’t stop – crystallization when the material is stretched.

By altering the number and types of linkers used, as well as how they’re distributed throughout the polymer network, the scientists were able to adjust the material’s stability and precisely set the melting point at which the shape change is triggered.

Heating the new polymer to temperatures near 35 degrees Celsius, just below the body temperature, causes the crystallites to break apart and the material to revert to its permanent shape.

“Our shape-memory polymer is like a rubber band that can lock itself into a new shape when stretched. But a simple touch causes it to recoil back to its original shape,” Prof. Anthamatten said.

_____

Yuan Meng et al. Body temperature triggered shape-memory polymers with high elastic energy storage capacity. Journal of Polymer Science Part B: Polymer Physics, published online January 13, 2016; doi: 10.1002/polb.23990