A group of researchers at the University of Illinois at Urbana-Champaign has designed an automated ‘3D printer’ for small molecules that could open the power of customized chemistry to many.

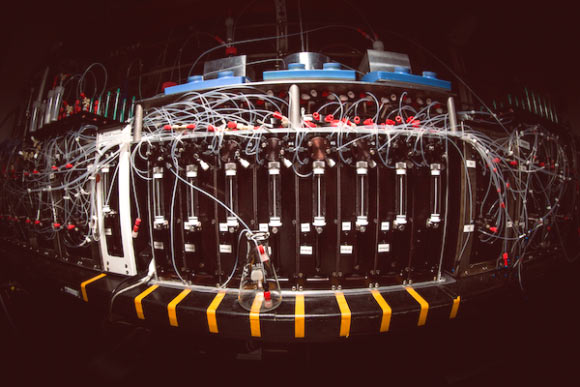

This synthesizer assembles complex small molecules out of simple chemical building blocks, like a 3D printer on the molecular level. Image credit: L. Brian Stauffer.

Small molecules are a specific class of complex, compact chemical structures found throughout nature. They are very important in medicine – most medications available now are small molecules – as well as in biology as probes to uncover the inner workings of cells and tissues. Small molecules also are key elements in technologies like solar cells and LEDs.

“Small molecules have already had a big impact on the world. But we’ve barely touched the surface of what they’re capable of achieving. In large part, that’s because there’s a major synthesis bottleneck that precludes accessing all of their functional potential,” said team leader Dr Martin Burke, who is the senior author of a paper published in the journal Science.

Chemists almost always develop a customized approach for manufacturing small molecules, designing a series of chemical reactions that, when applied to the right starting materials, yield the desired product.

“Every time you make a molecule you have to develop a unique strategy. That customization is slow. Currently you have to have a high degree of training in synthesis to make small molecules,” Dr Burke explained.

Plants, animals, and microbes manufacture many small molecules with protein-like functions, and with some precise chemical modifications, Dr Burke suspects it may be possible to optimize some of these natural products to mimic the function of missing proteins enough to restore patients’ health.

To do that, Dr Burke’s team needs to synthesize and test not just the small molecule found in nature, but also new versions with targeted modifications.

“Making those molecules is a major barrier to drug discovery. Doing real atomistic modifications to transform nature’s starting points into actual medicines is really, really challenging. The slow step in most cases in the synthesis. As a result, many natural products don’t get worked on in any practical way.”

The scientists took cues from nature to streamline the synthesis of the molecules they were studying, developing an approach that they have now expanded to make more general.

“Nature makes most small molecules the same way. There are a small number of building blocks that are coupled together over and over again, using the same kind of chemistry in an iterative fashion.”

To automate the building-block assembly, Dr Burke and his colleagues devised a simple catch-and-release method that adds one building block at a time, rinsing the excess away before adding the next one.

They demonstrated that their small-molecule synthesizer could build 14 different classes of small molecules, including ones with difficult-to-manufacture ring structures, all using the same automated building-block assembly.

The scientists have developed hundreds of these chemical building blocks and made them commercially available.

“But it’s not really about the numbers. We are showing that with a very reasonable number of building blocks we can make many different types of natural products,” Dr Burke said.

_____

Junqi Li et al. 2015. Synthesis of many different types of organic small molecules using one automated process. Science, vol. 347, no. 6227, pp. 1221-1226; doi: 10.1126/science.aaa5414

![Chemical structure of the cyclo[48]carbon [4]catenan. Image credit: Harry Anderson.](https://cdn.sci.news/images/2025/08/image_14141-Cyclo-48-Carbon-104x75.jpg)