Sometimes, studying past technologies leads to remarkable discoveries that can help design better materials for the future. This is the little known science of Archaeomimetics, i.e. the development of new technologies and materials inspired by ancient crafts and cultures.

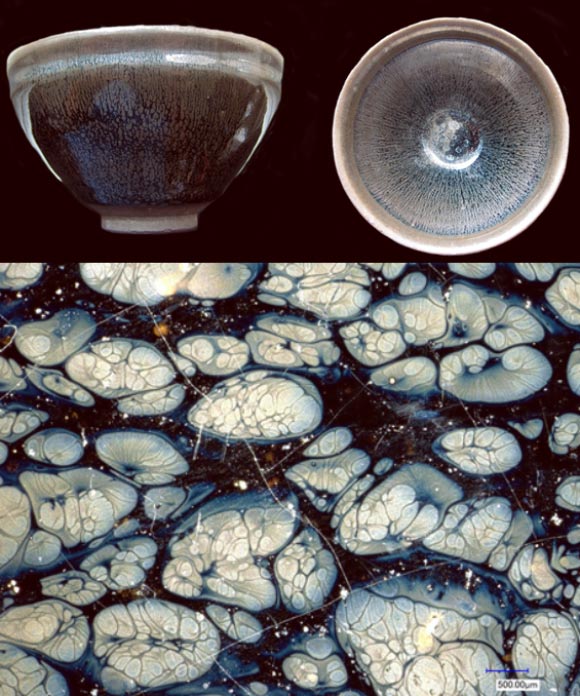

Top: modern replica of a Tenmoku tea bowl with oil spot surface patterns. Bottom: close-up of the oil spot pattern from an ancient Jian ware. Credit: Weidong Li / Zhi Liu.

The skillful potters of the Song dynasty (960-1279 CE) in the Fujian province of South East China have produced some of the most exquisite wares in the ancient world: the famous Jian bowls are characterized by their shiny black glaze exhibiting incredibly rich and variable brown or silvery surface patterns.

They were so prized, indeed, that three of the four surviving Jian wares brought to Japan by Japanese Buddhist monks during the 14th century were designated as National Treasures in the Rising Sun Archipelago where they are called ‘Yohen Tenmoku.’

Jian wares were produced in large quantities inside large ovens called kilns. Temperature and atmosphere were highly dependent on the exact location inside the kiln, explaining the surprising variety of motives that can be produced in the glaze.

The majority of the bowls exhibits brownish streaks called ‘Hare’s fur’ patterns. More rarely, silvery round spots form the so-called ‘oil spot’ patterns.

Jian ceramics were made using the local iron-rich clay and their surfaces were coated with a mixture made of local clay, limestone and wooden ash. Inside the kiln, temperature reached values of about 1,300 degree Celsius (more than 2,300 F), enough to melt the coating which will eventually form the glaze. Oxygen bubbles in the liquefied glaze moved iron ions to the surface. As the glaze turned into glass during the cooling process, molten iron-flux flowed down the sides of the potteries and crystallized into iron oxides.

Based on colors, it has been assumed that the iron oxides that formed in the ‘Hare’s fur’ patterns were of the mineral hematite, while the ones that crystallized in the ‘Oil spot’ patterns were crystallized as the mineral magnetite.

However, a new study published in the journal Scientific Reports indicates that this is not the case and the results are astonishing.

The study was conducted by an international team consisting of Catherine Dejoie, Philippe Sciau and Laure Noé from France, Weidong Li, Kai Chen, Hongjie Luo and Zhi Liu from the P. R. China and Apurva Mehta, Martin Kunz and Nobumichi Tamura from the United States.

Combining different approaches including optical microscopy, electron microscopy, Raman spectroscopy and synchrotron x-ray techniques, the team showed that the crystals contained in the ‘Oil spot’ Jian bowl glaze and responsible for the silvery patterns consists of a high purity ε-Fe2O3 phase (the epsilon phase), a very rare and metastable relative of the mineral hematite.

The ‘Hare’s fur’ glaze also contains the ε-Fe2O3, but in small quantity, mixed with hematite.

“We have these crystals that must be iron oxides based on their chemical compositions but for which the x-ray diffraction data and Raman spectra do not match any of the common iron oxide minerals, such as hematite, maghemite or magnetite. In the end and out of despair I tried this epsilon phase that no one would have thought of and to my surprise, I obtained a perfect fit,” said Dr Catherine Dejoie of ETH Zurich, the lead author of the study.

“As we learn more about this epsilon phase, we got the feeling that we just stumbled upon something much unexpected and potentially very important to our modern world,” added co-author Dr Philippe Sciau of CEMES.

The surprise of the scientists is legitimate as the elusive epsilon-phase has only been identified in 1934 and its crystalline structure was unknown until 1995 and only fully understood in 2005.

What makes this compound technologically so interesting is that in 2004, it was discovered to have a giant coercivity value of some 20,000 Oersteds. Coercivity is a measure of the ability for a material’s magnetization to withstand changes induced by an external magnetic field, and thus is an important property for the usefulness of permanent magnets.

The coercivity value for the epsilon phase is more than twice the value of materials currently used in electronic storage media and magnetic stripe cards (i.e credit cards), such as barium hexaferrite BaFe12O19.

Moreover, there are reasons to believe that the epsilon phase is magnetoelectric, i.e. its magnetic property can be influenced by an electric current and vice versa.

This is interesting in applications where one wants to change an electric current by a variable magnetic field, such as very compact and energy-efficient electronic components. The fact that it only contains two elements, iron and oxygen, both of which are found in abundance on earth, makes the prospect of wide scale applications of the epsilon phase economically very attractive.

But there is one big problem: it is very hard to make.

Modern synthesis techniques have only managed to grow tiny crystals, which moreover always contain some amounts of contamination from other phases such as hematite.

In the Jian bowl with ‘Oil spot’ pattern, the epsilon phase is pure and was grown as crystals an order of magnitude larger than its modern synthetic counterpart.

It also has an interesting 2D intricate microstructure with interesting optical properties, which are responsible for the remarkable silvery look of the ‘Oil spots.’

“The ancient Chinese unwittingly used a non conventional pathway to produce the epsilon phase and understanding how they did it is a key that could lead us to a breakthrough for potential applications” said co-author Dr Weidong Li from Shanghai Institute of Ceramics.

In other words, the ancient Chinese have succeeded to stabilize a unique phase in their Jian bowls that can be of immense technological importance in the future.

______

C. Dejoie et al. 2014. Learning from the past: Rare ε-Fe2O3 in the ancient black-glazed Jian (Tenmoku) wares. Scientific Reports 4: 4941; doi: 10.1038/srep04941